Your Cart is Empty

FREE SHIPPING ON ALL WINCH & AIR COMPRESSOR ORDERS - AUSTRALIA WIDE!

FREE SHIPPING ON ALL WINCH & AIR COMPRESSOR ORDERS - AUSTRALIA WIDE!

Safe and Reliable Winch Wiring Practices

March 09, 2016 5 min read

Installing a winch on your 4x4 is a great upgrade that can often be done in a day by the average home automotive enthusiast. Having an understanding on how the winch works provides an appreciation of the importance of safe and effective wiring practices.

Sherpa 4x4 Winches incorporate one or two series wound DC electric motors. The motors have a power rating of up to 6.6hp and can draw in excess of 400 amps under full load.

About the winch solenoid

The winch solenoid is designed to quickly switch the high amperage load the winch requires, minimising the opportunity for sparking and burning of the solenoid internal contactor terminals. Some high quality solenoids, such as those supplied with Sherpa 4x4 winches, are over engineered with silver contact tips and higher current ratings. The silver contacts help to prevent sparking and heat at the contact surface and reduce the opportunity for contacts to weld close. Sherpa 4x4 solenoids are rated to 500 amps load under winching operations and result in a high reliability switching device.

A problem sometimes experienced when winching is solenoid ‘doorbelling’ or ‘Hunting’. This is where the solenoid makes a high frequency chatter when the user tries to winch in. This chatter is a result of the solenoid coil not having enough voltage to sustain an energised closed circuit. A number of causes can lead to this situation and these are explored below;

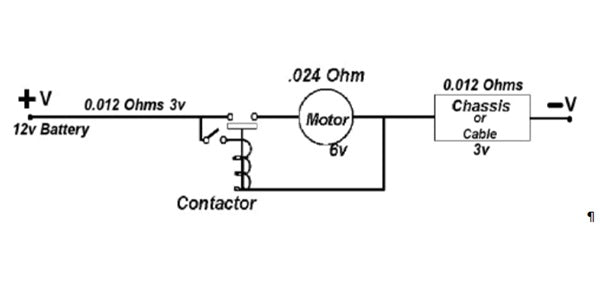

Excessive voltage drop in wiring

Every electrical wire has a resistance which is measured in Ohms. The resistance value is essentially a function of the cable cross sectional area and purity of the copper used to make the cable. Resistance impacts the winching operation by causing voltage drop along the electrical cables. The resistance has greater impact on the voltage drop as the current draw along the cable increases. Winch motors are very high current drawers (in excess of 400 amps) and therefore the electrical cable resistance is extremely important and must be minimised. Taking a 12v winch as an example, the battery powering the winch presents as ~12.4v at the battery terminals. Under winching situations users might see up to 3V of voltage drop in the cables running to the winch motor and another 3V in the return loop to the battery. This leaves only 6V for both the solenoid and winch motor to share. The image below helps to illustrate;

In this situation, the voltage may drop to a level unable to sustain the energised, closed contact solenoid. As a result, the solenoid opens, stopping the current flow to the motor. As the current flow to the winch motor has now stopped, the voltage drop in the cables reduces. The voltage now returns to a level adequate to energise and close the solenoid contact. The cycle now repeats itself with the winch motor again drawing current and the previous cable voltage drop returning. The process repeating in short duration presents as ‘chatter’. If this ‘chatter’ continues, the tips of the contactor will become hot and eventually weld themselves shut damaging the solenoid and causing the winch to ‘stick’ on.

Installers should ensure appropriately sized cables are used when wiring winches. Sherpa 4x4 has done the hard work for the installer and provides each winch with correctly sized, high quality, pre-terminated battery cables. For a typical installation, simply follow the instructions provided and attach the cables to the identified, colour coded terminations.

Excessive voltage drop in terminals and connections

The connection where a cable attaches to a battery or the winch is another common location for excessive voltage drop leading to winch ‘chatter’. Terminals may ‘appear’ to be ‘touching’, however unless tight, will result in high resistance and voltage drop. Similarly, terminals can become dirty contributing to voltage drop.

Winch installers should ensure terminals are correctly tightened with spring washers to prevent terminal nuts vibrating loose over time. A small amount of ‘loctite’ or similar product may be used to aid.

Earthing via vehicle chassis

Most vehicles on the market run a negative vehicle chassis earth meaning the starter batteries negative terminal is connected to the vehicle chassis. This means it is possible to connect the winch earth cable to the vehicle chassis rather than running it back to the battery terminal negative post. Wiring in this manner is common in larger trucks where the winch may be rear mounted far away from the primary battery. Connecting the negative wire back to the chassis saves running a heavy gauge cable over the length of the truck. Whilst this method of completing the electrical loop can work if performed correctly, it’s not recommended for novices and should only be used where alternate solutions are not practical.

Sherpa 4x4 winches are provided with enough electrical cable to suit a standard vehicle install. Extra long battery leads are also available as an option.

Poor Battery Condition

Winch owners should ensure their vehicle batteries are in good condition and are holding voltage prior to relying on their winch to get them out of trouble. Tired batteries may still turn over a starter motor, however can quickly drop voltage when under winching conditions and display the ‘chatter’ character of operation.

Failure to winch with engine running

Users should ensure their vehicle engine is running whenever they are attempting a winch recovery. A well maintained vehicle electrical system will boost the battery voltage when the engine is operating. Many vehicle alternators will output higher voltage at higher RPM and therefore using the vehicles ‘idle up’ functionality, where available, can also assist. A running engine also aids by charging the battery as the winch consumes power.

Incorporation of an electrical isolator

Sherpa 4x4 recommends installers incorporate a suitably rated electrical isolator in their electrical wiring. The isolator should be installed as physically close to the battery as possible. There are safety concerns that should be addressed with running heavy gauge, active electrical cables from the battery to a winch at the front of a vehicle. For example, if the vehicle was in an accident, could the active cabling become crushed and pinch against the negative earthed chassis of the vehicle? Being as the winch cabling is such heavy gauge, what would a dead short look like? Could a fire be started?

Sherpa 4x4 offers heavy duty electrical isolators which are rated for 500 amps of continuous duty and can take peak current loads up to 2000 amps for 10 seconds. The isolator is a worthy insurance policy and provides peace of mind knowing your winch is only energised when you turn the isolation key.

Routing of cables

As discussed above, cables have the ability to become pinched and earth, short-circuiting the battery if not correctly installed. Chaffing of cables is common over time when not installed within conduit with adequate restraint. Care should be taken when selecting the cable routing path to avoid sharp edges along with exposed screw ends. Installers should re-check their work after 1 week of driving and then again at 3 month intervals to ensure no new chafing or movement of terminations is occurring.

Planning and special attention during your winch installation will ensure you enjoy many years of adventures with your Sherpa 4x4 winch.

If you have any further questions or queries, please do not hesitate to contact one of the Sherpa 4x4 staff via info@Sherpa4x4.com.au or call on 1300 246 406

Leave a comment

Comments will be approved before showing up.

Subscribe

Sign up to get the latest on sales, new releases and more …